Return to News

Our progress on responsible materials

September 24, 2025

Sustainability

4 min read

KMD Brands has set a group-wide goal for responsibly-sourced materials in our own brand products – and in FY25 we made significant progress towards that ambition

Kathmandu changes the fabric of performance

Kathmandu has achieved its goal of sourcing 100% of wool from Responsible Wool Standard (RWS) certified sources in 2025.

“Reaching 100% RWS wool is a proud milestone but it’s only the beginning. Our next frontier is scaling innovations like carbon-capture technology, bio-based synthetics, and textile-to-textile recycling. We envision a future where the textile industry is 100% fossil-free,” says Manu Rastogi, Head of Product Innovation & Product Sustainability, Kathmandu.

Kathmandu’s award-winning Women’s Seeker Lined 4” Shorts show how science and design can change the very fabric of performance. The primary material is LanzaTech’s carbon-capture polyester, created by turning steel mill emissions into ethanol and then into polyester. Q-CYCLE® nylon by Fulgar adds a second breakthrough, converting discarded car tyres into high-performance yarn through advanced recycling processes.

Light, breathable and durable, the Seeker Shorts deliver for customers while also pushing the boundaries of sustainability. This year, the garment earned international recognition with an ISPO Award, the jury praising Kathmandu for “transforming emissions into new raw materials.”

Polyester products are also on the path to transformation, with 72% of apparel and 45% of equipment polyester made from recycled materials. “We’ve worked hard to improve our data collection this year. That transparency is a win in itself – giving us a clearer baseline for further improvement,” Manu notes.

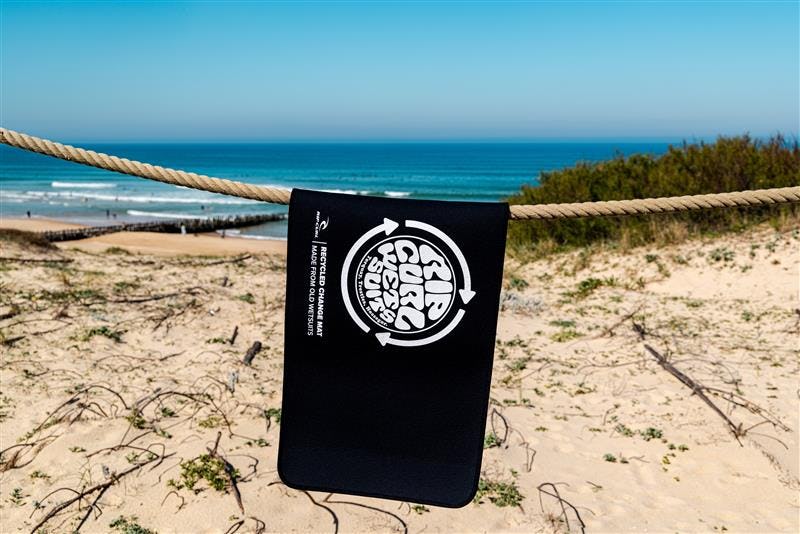

Rip Curl rides the fibre wave

At Rip Curl, sustainability is stitched into our surf DNA. Our goal is for 100% of apparel and accessories to contain preferred materials by 2030 – and we are making steady progress. In FY25, 75% of apparel and accessories included preferred fibres, up from 30% in FY22.

In FY25, 81% of cotton was responsibly sourced and almost half of our wetsuit range (47%) was made with responsibly sourced materials – nearly double the previous year. The new Rip Curl Planet landing page showcases our preferred materials.

“Rip Curl is on a journey, and the closer we get to 100%, the tougher the challenges become. But every new project brings fresh insights, new lessons and opportunities to innovate – helping us build better products and a lighter footprint,” says Milan Thompson, Head of Product Innovation & Sustainability, Rip Curl.

One opportunity is Rip Curl’s partnership with BLOOM™, which transforms algae into environmentally friendly materials like foam and rubber. BLOOM’s production process captures carbon, reduces emissions, restores ecosystems and returns clean water to the environment. In FY25, our partnership restored nearly 62 million litres of water to natural ecosystems.

Oboz treads with a lighter footprint

Oboz is rethinking every material that goes into its footwear. In FY25, the brand eliminated intentionally added PFAS, or per- and polyfluoroalkyl substances, from all non-wicking treatments and waterproof membranes. Independent testing by Intertek confirmed Oboz products are now free from intentionally added PFAs, hitting our 2025 target.

This breakthrough builds on earlier achievements, such as sourcing 100% of leather from tanneries certified to the Leather Working Group’s Gold standard – the highest rating for environmental and chemical management.

Lessons from the development of the Cottonwood Collection have also helped us to refine our approach. Cottonwood styles feature at least 34% environmentally preferred materials by weight, thanks to a design process that scrutinised every component.

The proportion of styles meeting Oboz’s 20% environmentally preferred materials threshold almost doubled in FY25, climbing to 64% compared with 34% in FY24. All shoelaces and linings are now made with GRS-certified recycled fibres, for instance.

“Eliminating intentionally added PFAS ahead of schedule shows what focused collaboration between Oboz, our factory partners and material suppliers can achieve. Every material decision counts, and it all adds up to footwear that treads a little bit lighter on the planet,” says Dan Wehunt, Senior Director of Product, Oboz.