Return to News

Our progress on circularity

September 24, 2025

Sustainability

4 min read

KMD Brands has set a goal to advance commercialised, brand-led circular business models - and in FY25 we continued to make progress towards this ambition

Rip Curl

When Rip Curl first began repairing wetsuit and watches nearly 40 years ago, we didn’t call it ‘circularity’. It was simply common sense and good customer service. Today, that ethos has grown into a global commitment to keep products in circulation for longer and materials out of landfill.

As a foundation member of Seamless, Australia’s national circularity scheme, Rip Curl continued to build its capability in sustainable design this year.

Designer, Eleanor Jermy, completed a circular clothing design implementation course, gaining practical skills to support circular principles in our products. Reflecting on the experience, Eleanor said: "Circularity is so broad and all-encompassing, so it’s great to be a part of Rip Curl’s journey as we look for ways to make a positive difference in this space."

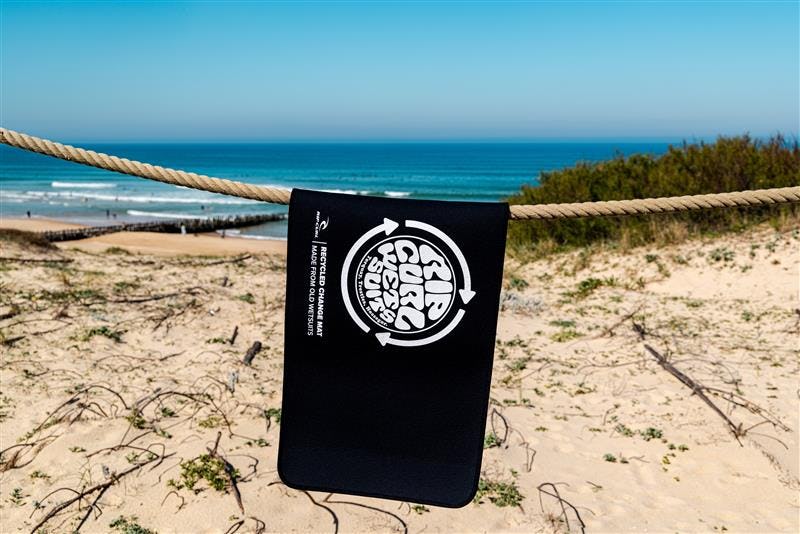

The Recycle Your Wetsuit program is now in its fifth year and has diverted more than 77,000 kilograms of neoprene – almost 64,000 wetsuits – from landfill. Operating across 66 locations in Australia, the USA, Spain, Portugal and France, the program gives old wetsuits a new life.

In Europe, recycled neoprene from the program is being transformed into products like change mats, with open-toe footwear on the horizon. Rip Curl also recycled 1,870 kilograms of textile waste from our head office, including fabric swatches and unsellable samples, through Upparel. While our wetsuit factory, Onsmooth Thailand, recycled another 142 tonnes of neoprene offcuts alone this year.

Repair services remain central to our circular approach, with on-site wetsuit repairs launched during the MEO Rip Curl Pro Portugal, in Peniche, and thousands of wetsuits and watches restored globally in FY25.

To connect our customers with these initiatives, we launched the Rip Curl Planet landing page so surfers can see how their gear is riding the wave of sustainability.

Kathmandu

Circularity at Kathmandu means renewal, repair, recommerce and recycling.

Our products are built to last, and when they can’t be sold as new, we explore ways to give them another life – through clearance, charity donations, staff sales or innovative programs like REDU.

Launched in 2023, REDU takes used, damaged or faulty garments that might otherwise end up in landfill and puts them through a full process of repair, washing and relabelling. Since launch, more than 6,000 garments have been renewed, proving that customers are eager to embrace recommerce.

In FY25, 2,281 garments were repaired in Australia, and 2,048 of these renewed items were sold in-store under the REDU label, generating AUD$153,734 in sales.

Our head office team repaired 832 REDU garments in preparation for the launch of our first New Zealand REDU pop-up in Christchurch. Another step towards a wider roll-out, Tower Junction launched at the end of July and is already proving popular with customers.

Partnerships play a vital role in Kathmandu’s circular approach. We recycled 5,104 kilograms of textile waste donated by Australian customers in store through our partnership with Upparel.

In New Zealand, our ImpacTex program collected 388 kilograms of used garments, bringing the total to 772 kilograms since its launch in August 2023. Of those collected, around 1,000 items have been donated to local charities, with the rest recycled into new products.

From REDU to recycling partnerships, Kathmandu is showing how circularity creates new experiences and value for our customers.